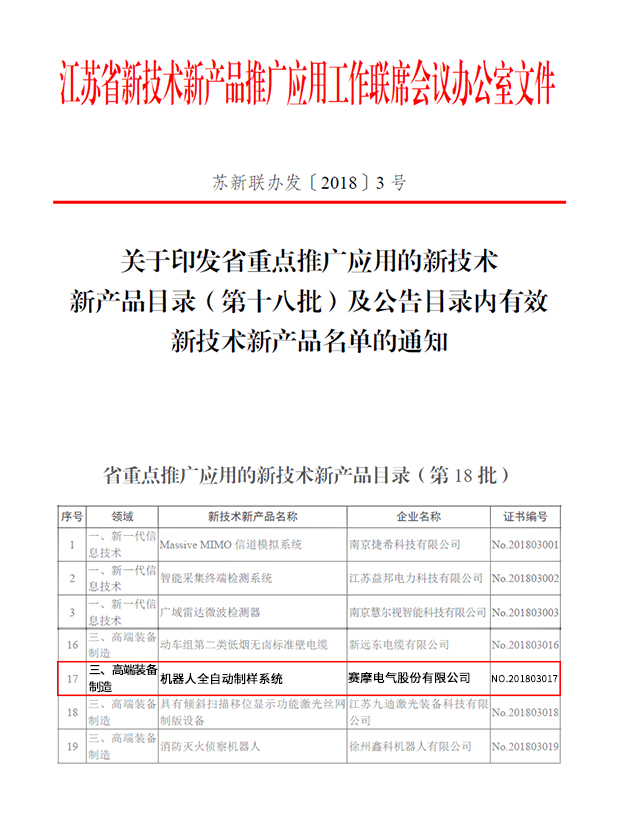

Saimo robot sample preparation system is listed in Jiangsu province high-end equipment promotion new technology

The robot automatic sample preparation system is mainly for the laboratory automatic preparation of coal raw coal sample samples, using the robot simulation experimenter sample preparation process and sample preparation action to carry out the automatic and orderly preparation of coal samples, and real-time monitoring of the sample preparation process. The sample information data is transmitted in real time, which realizes the whole process automation, informationization and sample safety traceability of coal sample preparation; it can be widely used in coal production, transportation, and consumer enterprises such as coal mine, port, thermal power generation, metallurgy, chemical industry and cement. .

Flexibility - flexible sample preparation

Flexible sample preparation process

Built-in multiple sample preparation schemes (preparation process, drying time, reduction ratio) automatically adjust according to sample parameters.

Sample plan remote setting

The system automatically selects the sample preparation plan.

Increase system flexibility

Built-in mixing device to ensure representative sample

Intelligence - using a constant mass reducer

The cutter opening and rotation speed of the reducer are adjustable, and the reduction ratio and automatic adjustment are automatically calculated according to the weight of the sample to ensure the constant quality of the retained sample and meet the relevant requirements of national standards.

The flow rate of the reducer is automatically adjusted, the feeding is uniform, and the representative sample is reduced.

The reducer is multi-purpose, and the different particle size (link) samples are automatically adapted.

Credibility - anti-cross-contamination in the sample preparation process

Washing the sample and washing the sample before and after grinding

The sample container is automatically cleaned with gas and a cleaning device

Pipeline and sample preparation equipment are automatically cleaned with compressed air

There are few sample preparation steps, the sample contact area is small, and the probability of cross contamination is greatly reduced.

The reducer is automatically adjusted and reused, and the same sample is used in the same step.

Visibility - automatic monitoring of system residual rate

All parts of the injection, sample retention, and discarded samples are weighed

The residual rate is automatically calculated, and the residual amount exceeds the standard automatic alarm.

Online full moisture analysis function, the results are automatically uploaded, the data does not fall

Ensure that the sample is sufficiently representative to meet the precision requirements

- Saimo Belt Scale continues to hold a post of ¡°Monomial Champion Product of MIIT¡±

- £¢New journey, Restart£¢, 2019 New Year's conference of Saimo Electric has come to a

- Saimo robot sample preparation system is listed in Jiangsu province high-end equipme

- Saimo Electric and Southeast University hold a school-enterprise cooperation licensi